WELCOME TO

HARIKRISHNA

PREFERRED MANUFACTURER OF INDIA

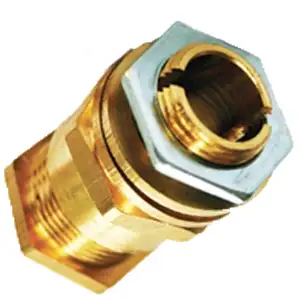

Our Products

We specialize in manufacturing metal components as an OEM provider, boasting a diverse array of products. Simply tell us what you need, and consider it done!

SINCE 2002

About Us

We are passionate about Manufacturing

With more than 20 years of manufacturing experience, we have developed a unique strategy to operate that enables us to provide the best experience to our customers. CORE STRENGTHof HariKrishna are..

Efficient Team

Quality Products

Punctual Delivery

Competitive Prices

There is much more about us, please visit our About Us page from the button below to get to know us better

KNOW MORECAPABILITIES

Our In-House Facilities

At HariKrishna Entech, we want to have total control over the quality of the product, which is why most of the manufacturing process is done in-house.

Over the period of time we have reached the stage where we can process many types of metal manufacturing process by ourselves, without relying on others!

We have our own foundryto cast the products before processing, so that we can control the quality of raw materials. Our sand casting facility can cast about 2 MTof metal per day. For extrusion and investment casting we partnered with well-established firms.

Learn more about Casting Process

Forging is a very important process for creating complex parts, where the cost of materials is relatively high; we do both Cold Forgingand Hot Forgingwith our 100 MT hydraulic press and 3 other 50 MT power press.

Learn more about Forging Process

Stamping facility is important for working with sheet metals and we have many products made of sheet metal, so we insisted that we have our own stamping facility to produce these parts.

Learn more about Stamping Process

Turning is the main process for metal-working, it is core process to manufacturing generic products, we have CNC turning centers lined up in the factory to get the lowest possible tolerances, but to achieve cost-effectiveness, we also installed manual turning machines (Lathes & SPM). We use both types of machines to get the best combination of precision and value.

Learn more about Turning Process

Not all parts are turned, some components require a milling process to be manufactured, for this requirement, we have CNC milling centers, as well as some CNC Turn-Mill centers so that the customer have everything under one roof.

Learn more about Milling Process

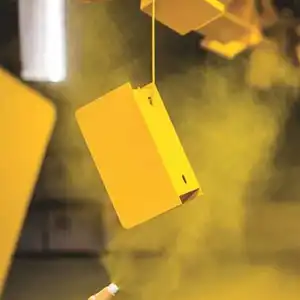

Finishing the surface is very important process, since it improves the visibility of the product, and in some cases, surface treatment is necessary to protect the parts from environmental and application wear and tear. We can do electroplating, knurling, glazing and powder coating inside the factory, but if client require any other type of surface treatment, we can also arrange one.

Learn more about Surface Finishing Process